Discovering the Manufacturing Process Behind Rubber Keypads and Their Significance in Modern Gadgets

Rubber keypads are crucial in the capability of contemporary tools. Their manufacturing procedure involves careful selection of materials and accurate strategies. Keypads are created to enhance user interaction while ensuring resilience and reliability. Understanding exactly how these parts are made discloses their significance throughout various applications. What variables add to their performance, and how do these components influence customer experience? The answers might reshape assumptions of this day-to-day technology.

Introduction of Rubber Keypads and Their Applications

Rubber keypads are functional elements widely made use of in various digital devices, varying from customer electronic devices to industrial tools. Their design permits a responsive response, making them a perfect option for applications calling for user interaction. Typically found in products such as remotes, calculators, and medical tools, rubber keypads assist in simplicity of use and availability.

In commercial setups, they offer vital functions in machinery and control panels, where longevity and resistance to environmental aspects are crucial. The non-slip surface area improves grip, advertising dependability in requiring problems. In addition, their lightweight nature and personalized forms allow producers to create customized solutions that fit details needs. With advancements in modern technology, rubber keypads proceed to advance, including functions like backlighting and improved level of sensitivity. Generally, their versatility and functional benefits add significantly to the effectiveness of numerous gadgets throughout several fields.

Materials Made Use Of in Rubber Keypad Manufacturing

Keypad making relies upon an option of products that improve both capability and sturdiness. The main material utilized in the production of rubber keypads is silicone rubber, understood for its superb durability and flexibility. This product allows keypads to endure duplicated pushing without losing form or efficiency. In addition, polycarbonate elastomers (TPE) are usually made use of due to their simplicity of molding and capability to give a soft-touch feel.

Tinting agents, such as pigments, are integrated to guarantee vivid, resilient shades that boost aesthetic charm. Additionally, ingredients like anti-UV representatives and flame retardants may be combined into the rubber to enhance weather condition resistance and security compliance. The choice of materials directly influences the keypad's tactile action, long life, and total performance in various gadgets. Inevitably, the careful choice of these parts is vital for the production of premium rubber keypads that fulfill customer and industry demands.

The Layout Process of Rubber Keypads

When developing rubber keypads, the layout process plays a vital duty in identifying performance and individual experience. Designers begin by defining the keypad's planned usage, taking into consideration elements such as the tool it will come with and the target individual demographic. This initial stage consists of sketching layouts that focus on ergonomic facets, making certain the secrets are conveniently obtainable and appropriately spaced.

Next, designers focus on the tactile feedback desired from the keypads, which affects the option of materials and key forms. Prototyping is important in this stage, allowing designers to test numerous layouts for comfort and responsiveness.

Manufacturing Techniques for Rubber Keypads

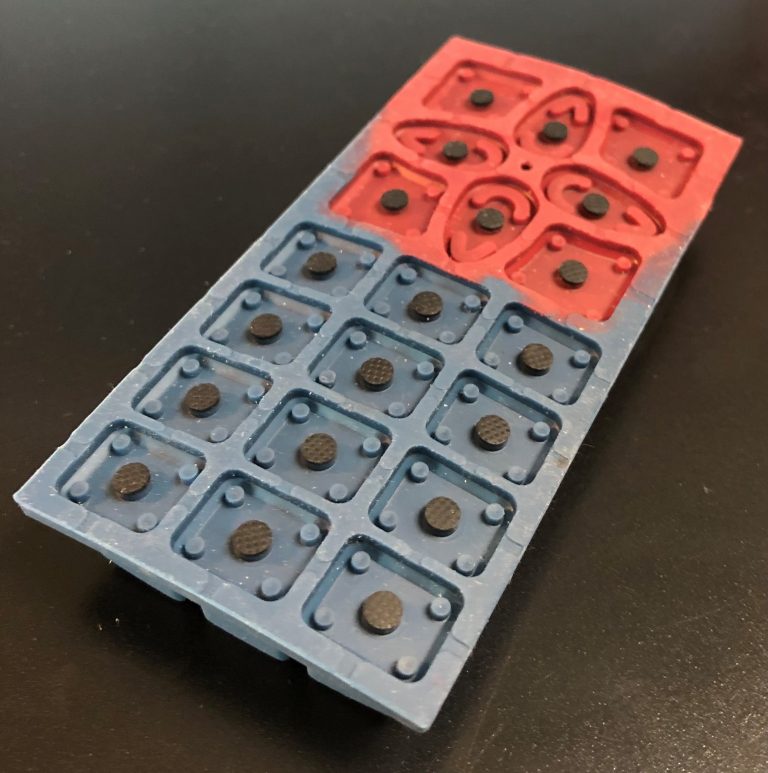

The production procedure for rubber keypads includes a collection of accurate methods that guarantee high quality and capability. Initially, liquid silicone rubber (LSR) is typically utilized due to its sturdiness and flexibility. The procedure starts with mixing the raw products, including silicone, colorants, and treating agents. This mixture is after that infused into molds made to shape the keypads accurately.

Adhering to shot, the shaped keypads undergo curing, a home heating process that strengthens the material (Rubber Keypads). This is typically performed in a press, ensuring the keypads attain the preferred firmness and strength

Quality Control Actions in Production

To assure that rubber keypads fulfill high criteria of top quality and performance, rigorous quality assurance actions are executed throughout the manufacturing process. These steps begin with basic material examination, ensuring that only the highest-grade elastomers are utilized. Throughout the production stage, operators carry out regular checks to keep an eye on specifications such as temperature, stress, and blending times, critical for accomplishing constant product high quality.

Post-production, each set of keypads undertakes extensive testing, consisting of tactile feedback assessments and toughness examinations to assess performance under various conditions. Visual evaluations are likewise performed to determine any type of issues, such as bubbles or variances in appearance. Additionally, conformity with industry standards is confirmed, ensuring that the Our site keypads satisfy safety and performance standards.

The Role of Technology in Keypad Development

Technology plays an essential role in the development of rubber keypads by making it possible for advanced manufacturing techniques that boost precision and performance. Furthermore, cutting-edge product selection enables improved sturdiness and responsiveness in keypad performance. These developments not just simplify production however likewise raise the total high quality of the last product.

Advanced Manufacturing Techniques

Improvements in production methods reinvent the production of rubber keypads, improving both efficiency and precision. Technologies such as shot molding and 3D printing have actually changed standard procedures, allowing suppliers to create complex styles with minimized waste and improved turnaround times. Automation plays an important duty in this development, simplifying production line and minimizing human mistake. In addition, computer-aided layout (CAD) software program permits detailed personalization, making sure that keypads meet specific user requirements. Quality assurance procedures have actually likewise progressed, incorporating real-time surveillance systems that identify issues early in the production cycle. These technologies not just boost the sturdiness and performance of rubber keypads yet also support the growing demand for tailored solutions in various markets, from consumer electronics to automobile applications.

Innovative Product Choice

The evolution of manufacturing techniques has actually paved the method for cutting-edge product selection in rubber keypad growth. Advances in polymer scientific research have actually introduced materials that enhance resilience, versatility, and tactile feedback. Suppliers currently utilize thermoplastic elastomers (TPE) and silicone substances, which provide exceptional resistance to put on and ecological aspects. These materials enable the development of keypads that can endure long term usage while preserving visual charm. Furthermore, the combination of additives and coverings enhances performance, such as enhancing grasp and minimizing rubbing. The choice of materials is necessary, as it directly affects the performance and long life of keypads in various gadgets, from customer electronics to commercial tools. This innovative strategy proceeds to form the future of keypad click this site style and usability.

The Impact of Rubber Keypads on Customer Experience

Rubber keypads considerably affect user experience with their boosted responsive action, which allows for even more accurate interaction. Additionally, their durability and longevity add to regular performance gradually, lowering the requirement for constant replacements. This mix of attributes makes rubber keypads a favored selection in numerous applications, inevitably influencing individual fulfillment.

Enhanced Tactile Feedback

Enhancing responsive action substantially influences user experience, particularly in devices that depend on keypads for communication. Rubber keypads offer an unique combination of gentleness and resilience, allowing individuals to really feel unique feedback with each press. This responses reinforces a feeling of control and accuracy, critical in applications ranging from mobile phones to industrial devices. Individuals often report higher satisfaction and performance when engaging with tools that feature properly designed rubber keypads, as they assist in quicker and a lot more exact input. Furthermore, the ergonomic layout of these keypads can lower finger fatigue, promoting longer usage durations without pain. On the whole, the enhanced responsive feedback offered by rubber keypads considerably adds to a more intuitive and pleasurable customer experience in modern technology.

Toughness and Longevity

A key element of customer experience with rubber keypads depends on their durability and longevity. These keypads are address developed to hold up against substantial usage, standing up to damage that frequently influences other products. The durable nature of rubber assurances that keypads maintain their functionality and look with time, which is important for devices often utilized in various settings. Customers gain from the integrity of rubber keypads, as they can sustain exposure to temperature, dampness, and dust changes without wearing away. This resilience not only improves user fulfillment yet likewise reduces the requirement for frequent replacements, inevitably contributing to cost-effectiveness for suppliers. Essentially, the sturdiness of rubber keypads considerably influences the general performance and user experience in modern devices.

Often Asked Concerns

The Length Of Time Do Rubber Keypads Generally Last in Devices?

Rubber keypads normally last in between 5 to 10 years, depending on usage, ecological aspects, and high quality of materials utilized (Rubber Keypads). Routine deterioration can shorten their lifespan, influencing capability and individual experience gradually

Can Rubber Keypads Be Personalized for Certain Applications?

Rubber keypads can indeed be customized for details applications, permitting changes in dimension, form, appearance, and color. This adaptability enables producers to produce tailored options that meet diverse individual demands and enhance performance in different devices.

Are Rubber Keypads Environmentally Friendly?

Rubber keypads are often ruled out eco-friendly because of their petroleum-based materials. However, innovations in lasting manufacturing practices and the growth of bio-based choices are slowly improving their eco-friendly influence in different applications.

What Prevail Problems Faced Throughout Rubber Keypad Manufacturing?

Common concerns encountered during rubber keypad production include irregular material high quality, mold issues, inappropriate treating times, adhesion failings, and challenges in accomplishing exact tactile comments. These troubles can lead to lowered product efficiency and consumer frustration.

How Do Rubber Keypads Compare to Other Kinds of Key Switches?

Rubber keypads supply a softer feel and quieter procedure compared to mechanical switches, which supply responsive responses. Nevertheless, rubber keypads might wear faster and do not have the precision that some individuals like in high-performance applications.

The primary product made use of in the production of rubber keypads is silicone rubber, known for its outstanding durability and flexibility. When creating rubber keypads, the design procedure plays an important role in establishing capability and customer experience. Rubber keypads greatly influence customer experience through their improved tactile action, which permits for even more specific interaction. Users commonly report greater complete satisfaction and effectiveness when communicating with gadgets that include properly designed rubber keypads, as they facilitate quicker and more accurate input. An essential aspect of individual experience with rubber keypads exists in their resilience and longevity.